145+ years of Excellence

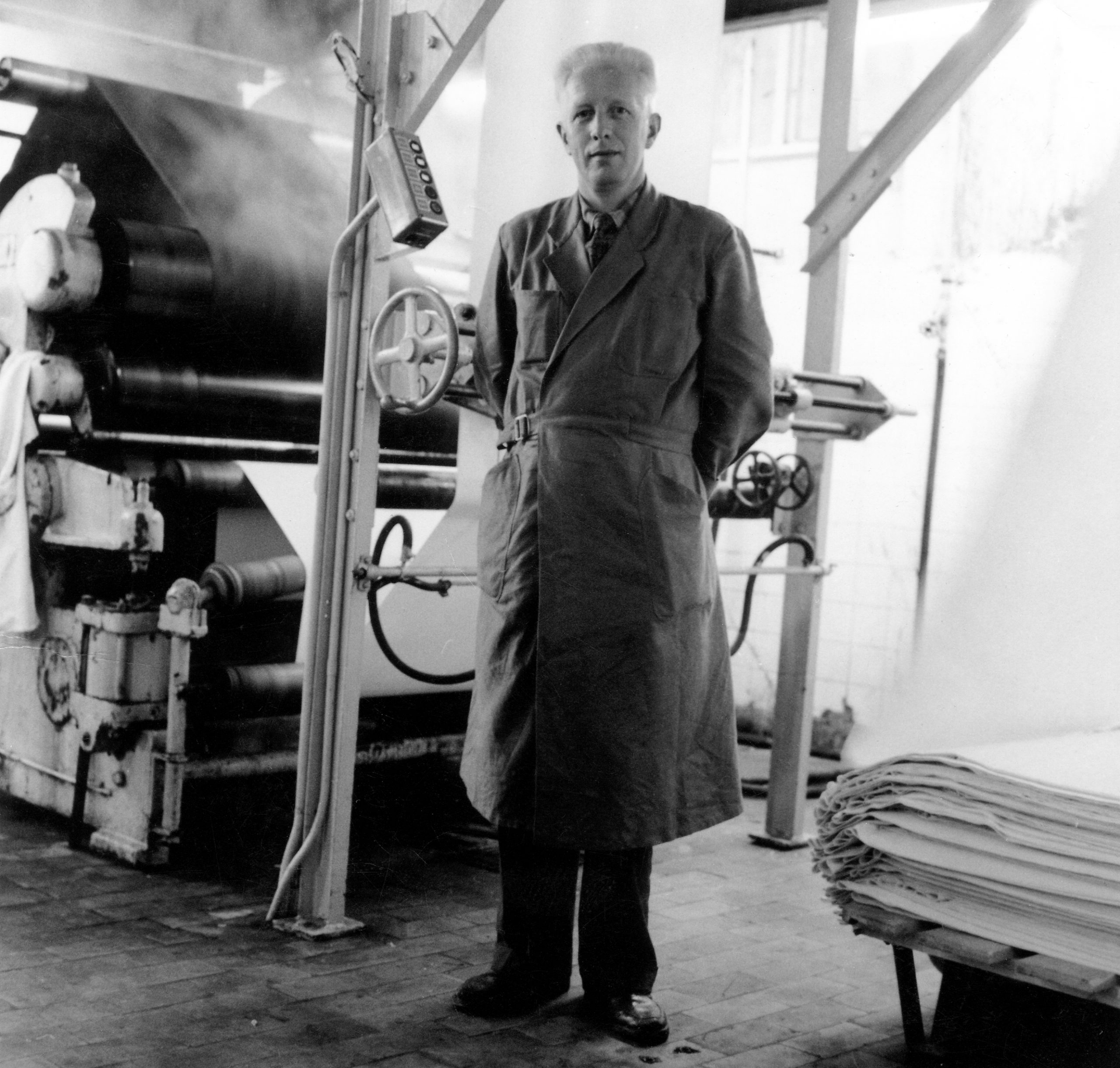

Journey of a Factory Manager – Jan Cleveland

Jan Cleveland

Former Factory Manager

Jan Cleveland retired in 2006, but in retrospect, he sometimes thinks he could have worked longer. He began his career at the factory in 1958, at the age of 17, with his first job being sweeping the floors. After some time, he attended trade school for a year and transitioned into an office role in Dale. There, he explored various areas of the factory, but textile work was always his clear calling.

A Career in Textiles

Jan pursued general textile studies in Sweden and upon his return to Dale, he was hired at the factory’s laboratory. His work included tasks such as inspecting cotton bales, which were imported from regions like Texas, New Mexico, and Brazil. These bales, weighing up to 250kg, were randomly sampled to ensure they met the necessary qualifications for weaving. At its peak, the laboratory employed seven individuals, both women and men.

The Golden Years

In the 1950s, the town of Dale had a population of around 3,000, with approximately 1,300 of them working at the factory. The factory was the largest and most important employer in the municipality, attracting workers from outside the region as well. Extra trains were scheduled each morning to transport commuters from Garnes, with some workers starting their shifts at 6 AM and finishing at 2 PM, while others worked from 2 PM until 11 PM.

During the dinner breaks, those living nearby would often go home to eat and rest before returning to their shifts. A large whistle at the factory signaled the end of the break.

Why Did It Succeed?

The factory’s success during this period can be attributed to the strong demand for textiles following World War II. There was a shortage of goods across various industries, including textiles, and about 30,000 people worked in Norway’s textile industry at the time. The golden years of the textile industry brought a population boom to Dale, but as demand eventually decreased, many workers had to seek employment elsewhere. Today, Dale’s population is approximately 60% smaller than it was during its peak.

Technological Advancements

While the fundamental processes in textile production remain largely unchanged, technological advances have significantly improved efficiency. Machinery now operates at greater speed and precision, enabling larger volumes of production.

Gender Dynamics in the Factory

Historically, the factory employed many women, particularly for tasks considered less complex. Women also contributed to the design process, though higher ranking positions were predominantly occupied by men. Today, the industry sees more women in leadership roles, reflecting broader changes in workplace gender dynamics.

Marketing Strategies

Dale products were popular across Norway, although not all items were sold directly from the factory. Some finished goods were distributed to sales offices in Oslo, Stavanger, Trondheim, and Bergen, where employees from Dale managed specific regions. Over time, the factory shifted to selling directly to customers. The U.S. and Canada were strong markets for knitting yarns, while woolen products saw the highest demand in the colder Nordic countries.

As Jan humorously notes, “It’s self-explanatory; that’s where it’s the coldest.”

Expertise in Textiles

Jan’s knowledge of textiles was vast. He brought a wealth of information about animals, vegetables, regenerated, and synthetic fibers, understanding their unique characteristics and various applications. He emphasized that there is a great deal to learn about fibers, as new varieties are discovered continuously by researchers.

Textiles, as Jan points out, is an expansive and ever evolving field with no limits. His passion for the industry was nurtured from an early age, growing up in a textile-oriented family. As he reflects, “The interest in textiles has probably rubbed off on me.”