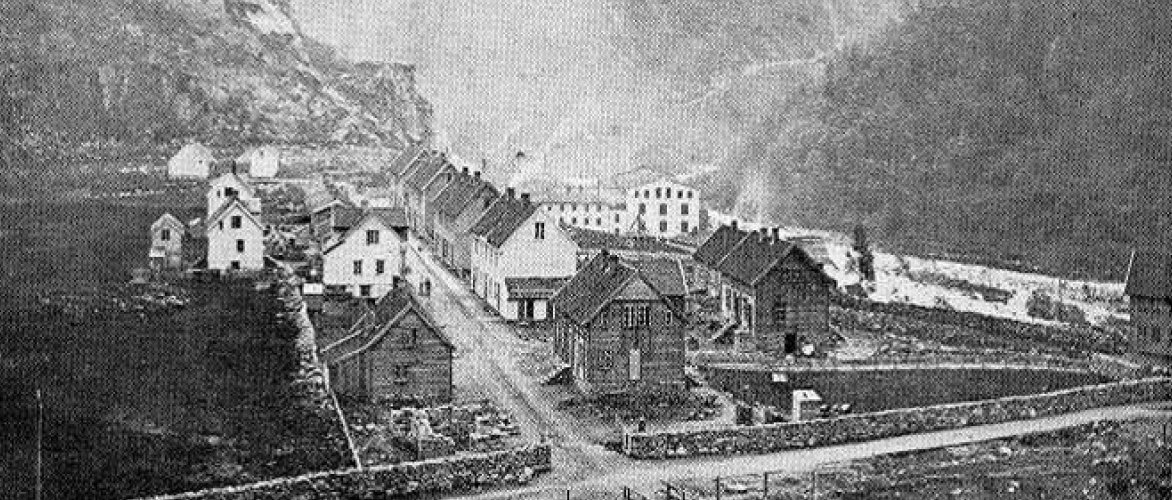

145+ years of Excellence

The 6th Generation Dale Factory Worker – Vegar Sellevold

Vegar Sellevold has been associated with Daletec since 1990, having undertaken various roles within the factory. His career reflects a genuine passion for his work.

Vegar grew up in Stanghelle during the 1970s and 1980s. At the time, many factory employees relocated from small apartments in Dale to homes in Stanghelle due to the declining conditions in Dale’s housing. During the early 1970s, the factory employed approximately 600–800 people, but by the time Vegar joined in February 1990, the workforce had decreased to around 300–400 employees.

Reflecting on his early career, Vegar recalls the relative ease of securing employment, particularly for those not pursuing higher education. He attended the gymnasium in Voss and initially pursued training as an electrician, but soon realized it was not the right path for him. In 1990, he decided to join the factory workforce.

A Magnet for Workforce Migration

When asked about the migration to Dale due to the factory, Vegar confirmed that the factory attracted workers from across the country, particularly during the pre- and post-war periods when a large workforce was required. Families often relocated together, with one member securing employment and accommodation, making it easier for other relatives to join them. However, wages were modest, prompting many to eventually settle in Stanghelle for better living conditions.

Skills and Roles in the Factory

Vegar explained that while some positions required specialized knowledge of textiles and electronics, many roles involved physical labor and required minimal training. He started in the cotton factory’s packing division, preparing large yarn cones for export. His responsibilities included packaging, managing warehouse logistics, and maintaining spinning machines.

After completing his military service, Vegar returned to find the weaving mill struggling. He was advised to seek a position elsewhere and soon transitioned to the finishing department, where he remained for several years. During this period, he pursued further training through the company, which sponsored his technical education in Germany. This opportunity allowed him to gain valuable expertise in textiles and engineering.

Upon his return to Dale, Vegar worked in the technical hall and later moved to the laboratory, where he became a dyeing assistant, testing and adjusting colors. He also pursued night courses in business and quality leadership to complement his technical background. Eventually, he was promoted to laboratory engineer and later transitioned to product development, where he has been contributing for the past 12–15 years.

Work Environment and Community

Throughout his career, Vegar appreciated the structured work hours and generous vacation policies. He never felt overburdened with long shifts and rarely worked weekends, except for overtime or travel. He fondly recalls the camaraderie among his colleagues, particularly in the mill and yarn storage departments. Celebrating birthdays with cakes brought by employees was a cherished tradition that he continues to honor to this day.

Although the workforce has significantly diminished, Vegar finds joy in his work. He values the collaborative and inclusive culture that has persisted over the years, despite the shrinking team.

Reflections on Career and Legacy

Vegar describes his career as varied, enjoyable, and rewarding. He feels fortunate to have had opportunities for professional growth and acknowledges the rarity of his expertise in textile processing within Norway. Globally, similar roles are more common, but in Norway, they are highly specialized.

The closure of production operations in Dale and the transition to Pakistan was a poignant moment for Vegar and his colleagues. While it was challenging to see many leave, the company has since invested in innovation, enabling employees to participate in international fairs and customer engagements.

A Sixth-Generation Factory Worker

Vegar takes pride in being a sixth-generation factory worker, continuing a family tradition that dates to 1879. His grandfather, Johannes Rønhovde, was among the skilled workers recruited by Consul Jebsen to establish the Dale factory. This legacy includes numerous family members across generations, reflecting a deep-rooted connection to the factory