145+ years of Excellence

Lifelong Loyalty – Working 45 Years in Dale – Frithjof Lampe

Lifelong loyalty – Working 45 years in Dale – Frithjof Lampe

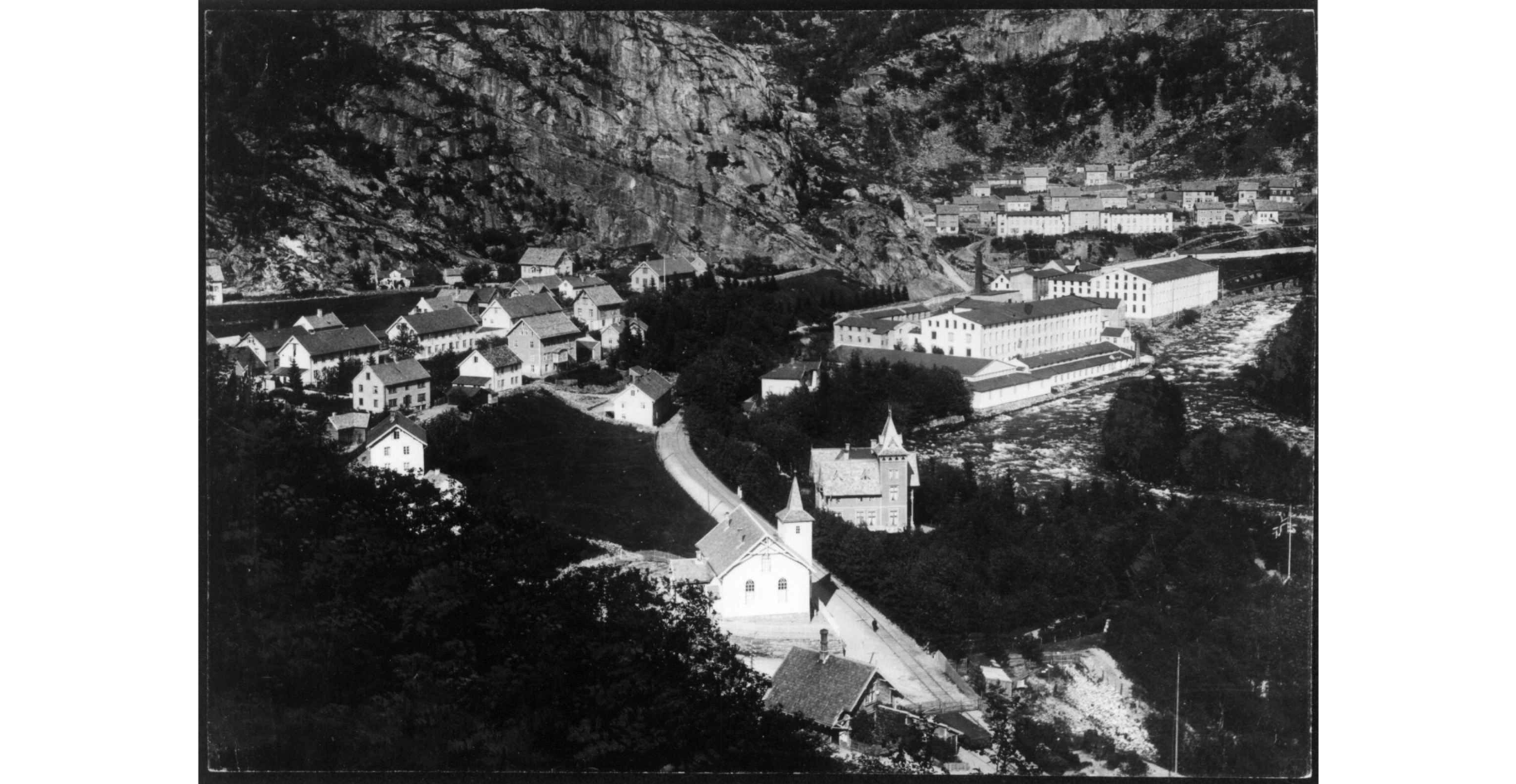

Frithjof Lampe was born in Bergen in 1932. At the age of 88, he remains vibrant and full of life, remarking, “This does not affect me.” His early years were shaped by the challenges of World War II, during which he attended a regular elementary school before moving on to a commercial gymnasium. Following his conscription in the Air Force, he began seeking employment, a journey that led him to Dale Factories in 1954.

Frithjof started his career in the sales and marketing department, working in an office located at Bryggen in Bergen. However, a devastating fire in 1955 destroyed the offices, necessitating a relocation. In 1982, the sales department moved to Dale, where Frithjof continued his work in sales and marketing, focusing on cotton fabrics. He fondly recalls this period as an “amazing working environment.”

When Frithjof joined Dale Factories, there were approximately 1,300 textile workers. He began his career with little knowledge of textile production but quickly rose to oversee the marketing of all Dale products, including woolen and cotton-based items, as well as bed linens introduced later. In 1967, he was promoted to section manager for fabric yardages, a role that came with the challenge of minimal exports and responsibility for a team within Norway’s sales department.

A Legacy of Loyalty

Frithjof’s 45-year tenure at Dale Factories was marked by his unwavering dedication and pride in the company. He valued strong relationships with employees across all levels, frequently interacting with staff on the factory floor to foster a sense of camaraderie and understanding.

He began his career at 22, at a time when the mercantile department did not demand advanced education. The starting salary was modest, at 500 Norwegian kroner per month, equivalent to about 6,000 kroner annually. Gender pay differences were minimal, and many families balanced work and childcare responsibilities by alternating shifts. Frithjof’s office hours typically ran from 8:00 AM to 4:00 PM, though public transportation often influenced work schedules.

Building Relationships and Expanding Markets

Travel was an integral part of Frithjof’s role. He signed contracts, nurtured client relationships, and ensured timely responses to customer inquiries to maintain trust and loyalty. Initially focused on domestic sales, he later spearheaded the establishment of export markets. Sweden was the first country outside Norway to purchase Dale’s goods, with a major clothing company ordering substantial quantities of satin fabric. Finland soon became a significant market for workwear, solidifying Dale’s presence in Scandinavia.

Frithjof took pride in his contributions to Dale’s success, particularly the transition from wool to cotton production in 1972, a move driven by cost-efficiency and market demand. This change was implemented without layoffs, as employees were reassigned to the expanding cotton division. The factory produced approximately 5 million meters of fabric annually and later adapted to the needs of the oil industry by developing flame retardant workwear.

Embracing Change and Innovation

Frithjof’s leadership was instrumental in navigating industry challenges, such as the shift from rail to truck transportation to meet customer demands for faster delivery. He also managed export relationships, particularly in Germany, where large contracts with major companies minimized the need for extensive market penetration.

Raw materials primarily consisted of American cotton, with higher quality, more expensive cotton sourced from Egypt. Dale’s success was bolstered by its skilled workforce, advanced product development, and strong documentation provided by its laboratory, which reinforced customer confidence in the superiority of Dale’s products.

Reflections on a Remarkable Career

Frithjof retired in 1999, but his fond memories of Dale Factories remain vivid. He attributes his professional fulfillment to the supportive work environment, dedicated colleagues, and the satisfaction of achieving success in his endeavors. Even after 20 years post-retirement, he and his former coworkers gather regularly, reminiscing about their shared experiences in textile production.

Looking back, Frithjof’s passion for his work and commitment to excellence were pivotal in shaping Dale Factory’s legacy. As he reflects with a smile, “It was an amazing workplace with a good environment. I would go back in a heartbeat!”